R&D Team

Our R&D team consists of industry experts and technical elites with extensive experience and innovation capabilities.

Our R&D team consists of industry experts and technical elites with extensive experience and innovation capabilities.

We possess a strong R&D team and advanced laboratory equipment, dedicated to innovative research in flavor capsule technology, providing safe and high-quality product solutions for our clients.

An advanced separation technology that, under high vacuum conditions, utilizes the differences in the average free paths of molecular motion among various substances to achieve efficient separation or purification of substances.

Through an integrated data collection, transmission, analysis and application system, a modern production system is achieved that is transparent, visualized, optimizable and adaptively controlled throughout the entire production process.

The key bridge connecting scientific hypotheses and empirical discoveries is constantly expanding the boundaries of human cognition and technology.

We continuously conduct cutting-edge technology research, driving innovation in flavor capsule technology and creating more value for our clients.

Developed mature technologies, combining green extraction & separation technology.Using non-tobacco materials to achieve baked & smoky tobacco notes.

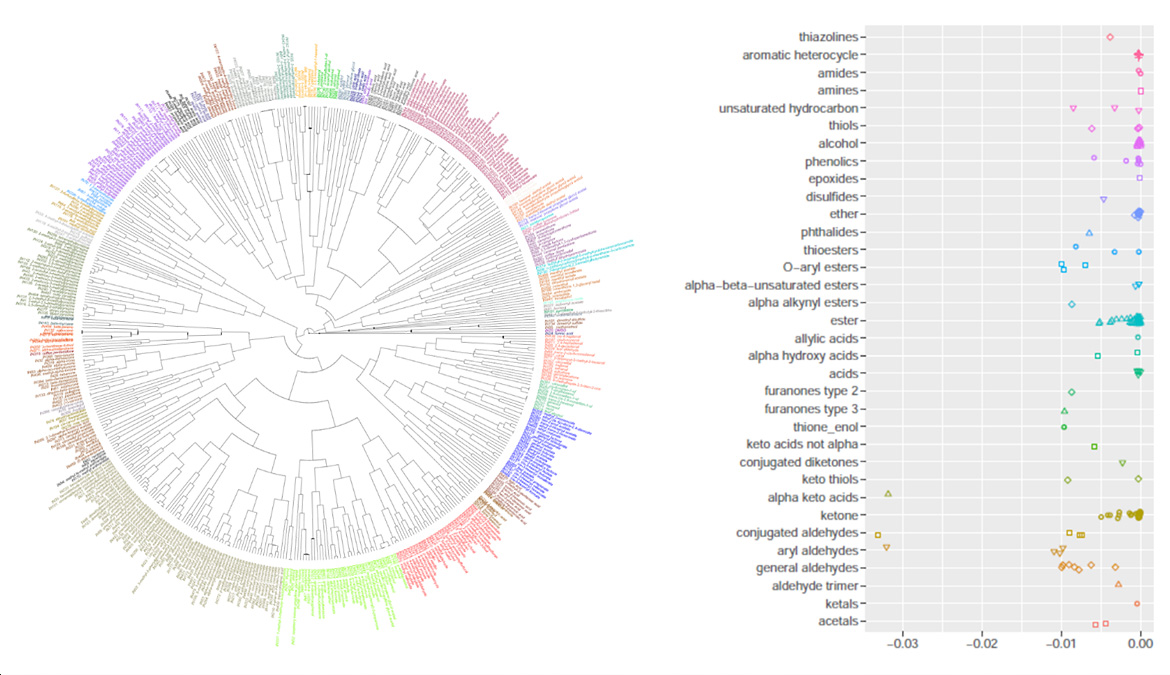

Established the first stability prediction model for flavor industry. Ensure the stability and safety during the shelf-life.

Dedicated IP team assisted with professional agents. Hychi filed 68 invention and utility patents, 13 are granted so far, covering 4 key areas. Actively sharing our IPs & know-how as part of overall commercial partnership.